Case Studies

Real world solutions to customer challenges

Here are a few examples of our work – with details on the challenge, and the process through to completed product. If you would like to see more examples of our work feel free to browse our product gallery (coming soon)

Our client wanted a replacement end dashboard vent for their Land Rover Defender. This was a complex shape to model due to the multiple angles, bevels etc.

It took a couple of iterations to get the exact dimensions right so it would clip in place perfectly. The end result was printed in a carbon-fibre reinforced nylon – it does the job and looks great.

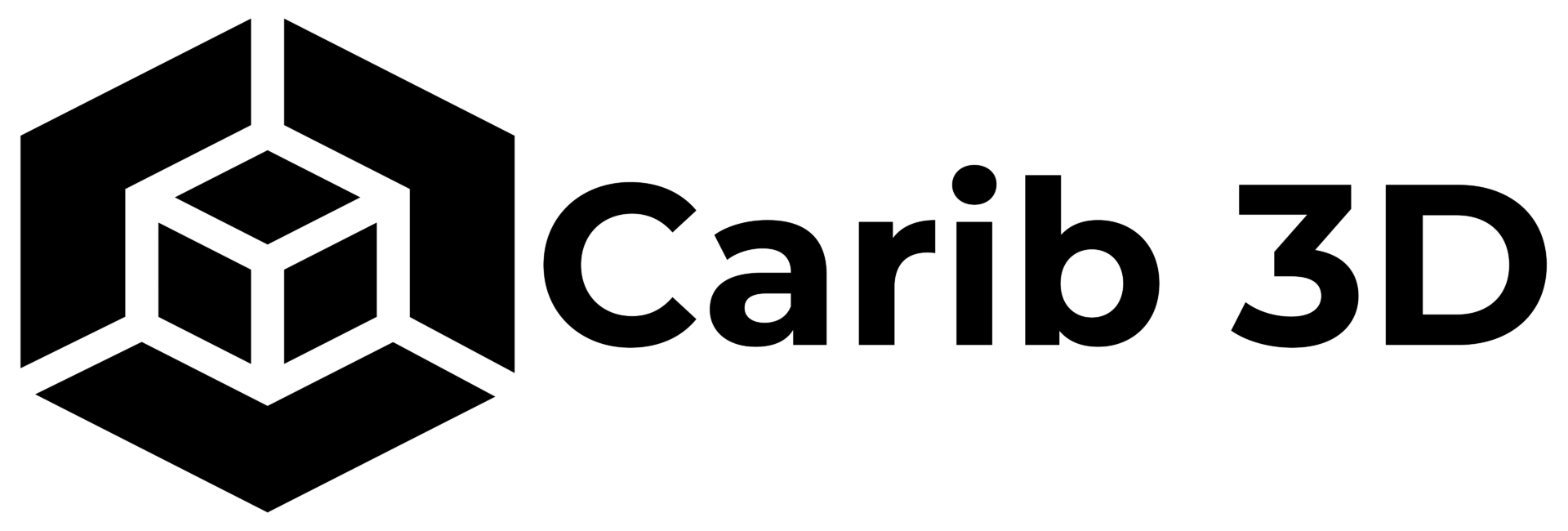

Interesting example of poor initial product design. These are hidden towel rail brackets. They screw to the wall, fit within a recess in the rail, and then a hex grub screw is used to fix the rail in place.

Unfortunately there is a gap at the base, plus a thin, sloping section in a soft metal for the grub screw to bite into. It is not very effective as teh screw grip loosens over time. This leads to towel rails that keep falling off the wall!

The problem was solved by creating a better design, with no central gap, and a full length threaded hole for the screw. Also, by printing in a carbon-fibre reinforced plastic we can ensure that the brackets are finally fit for purpose – and the towel rails stay where they belong!

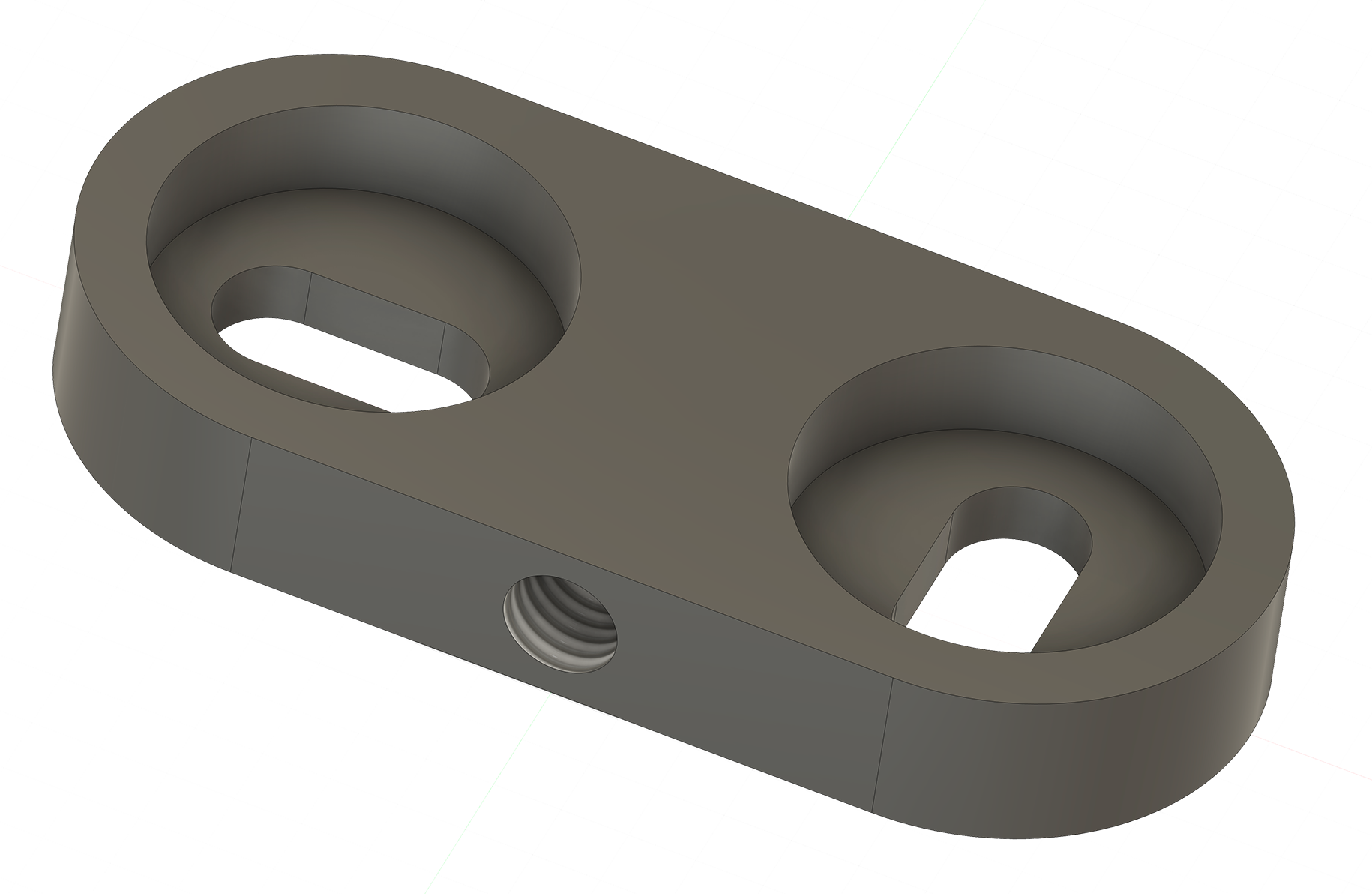

This has been one of our favourites so far! The client has a prototype high-performance Land Rover Defender. However the designers didn’t think to include sun visors – a definite necessity in Antigua. They were subsequently persuaded to create something – but the finished article was not up to the job.

Hence we were asked to design an alternative bracket that could fit around the vehicle roll case and hold the sun visors in place. The fit had to be just right – tight enough to grip the roll cage, but with enough play to allow deployment of the visor. Our design also allowed us to fix a major oversight of the original – where they had one of the hex screws facing the windscreen, making installation a nightmare! We could ensure that the hex heads pointed into the cabin, with captive nuts on the screen side, making installation a breeze!

LET’S MAKE SOMETHING!

GET IN TOUCH

Let us know what challenge you are trying to solve and discuss how we can help